Additive manufacturing is a booming technology, particularly in the medical field, and we have mastered the 3D printing implantable parts and instruments for the orthopedic market.

We can offer state-of-the-art manufacturing sites equipped with cutting-edge technologies in metal printing with laser (single and multi-laser printers) and electron beam melting (EBM) machines.

High capacity 3D printing

With tens of 3D printing machines at our disposal and a variety of equipment and processes in place, we are able to offer our customers the best solution available for the specific part they wish to produce. Indeed, with the different kinds of equipment we run, it is possible to achieve different surface finishes, details, and production speeds to meet the target properties, features, and price.

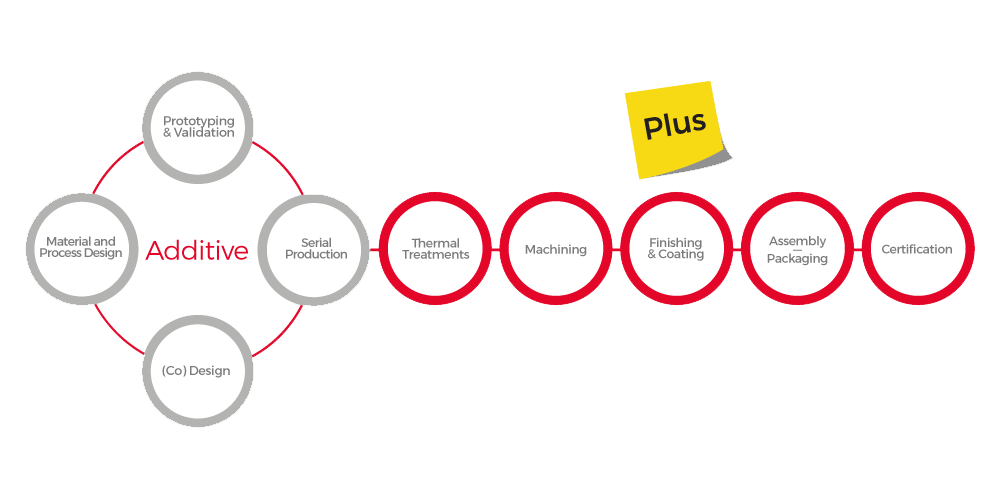

We support our customers from the design phase through to all potential post-processing needs. From thermal treatment, to machining, from surface modifications, to intermediate and final cleaning. Clean room packaging can close the additive manufacturing cycle if requested. Machining and mechanical post processes are run at our Lincotek Medical plants, where people have decades of experience in machining orthopedic implants and instruments.

Our complete offer of additive manufacturing and the all-round services allows for quick delivery and high control of the whole manufacturing process.

High capacity 3D printing

With tens of 3D printing machines at our disposal and a variety of equipment and processes in place, we are able to offer our customers the best solution available for the specific part they wish to produce. Indeed, with the different kinds of equipment we run, it is possible to achieve different surface finishes, details, and production speeds to meet the target properties, features, and price.

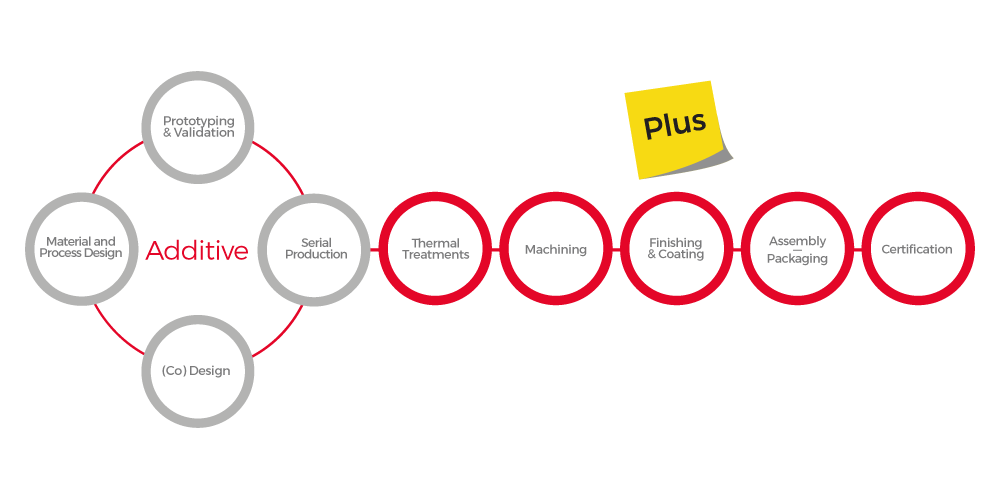

We support our customers with all the possible post-processes eventually required. From thermal treatment, to machining, from surface modifications, to intermediate and final cleaning. Clean room packaging can close the additive manufacturing cycle if requested. Machining and mechanical post processes are run at our NanoSurfaces plant, where people have decades of experience in machining orthopedic implants.

Our complete offer of additive manufacturing and the all-round services allows for quick delivery and high control of the whole manufacturing process.

/ Strong traceability and quality control

The implementation of in-process control tools in addition to the more traditional post-processing controls, allows us to have very strong traceability and quality control levels. Continuous research and development on 3D printing equipment and processes and on 3D printed materials gives us the possibility to offer our customers an outlook of the market in the future.

Design for additive, trabecular and porous structures, process control, process validation, surface modifications, post-printing processes, and cleaning processes are some of the additive manufacturing services we currently offer.

/ Extending the range of 3D printed materials

Looking toward the future, our research and development teams are focused on developing more innovative processes based on additive manufacturing principles. Moreover, they are working to extend the range of implantable materials that we can deliver via additive manufacturing, by including materials such as ceramics and plastics.

We use implantable-grade titanium and titanium alloys which comply with medical standards. Read about the properties of other materials used in the additive manufacturing process.

We have long-term expertise in manufacturing implantable devices using additive manufacturing techniques.

Our additive manufacturing paired services include machining of 3D printed components, smoothing and polishing, cleaning, and coating. We have several types of coatings that can be used, such as our Osprovit® HA coating.